Soil Stabilization

Soil stabilization is used for a number of activities. These include (1) temporary wearing surfaces, (2) working platforms for construction activities (3) improving poor sub-grade conditions, (4) upgrading marginal base materials, (5) dust control, and (6) recycling old roads containing marginal materials . A wide variety of materials have been used to stabilize soils or marginal aggregates (e.g., asphalt, Portland cement, lime and lime/fly ash, chemicals, salt, and other techniques).

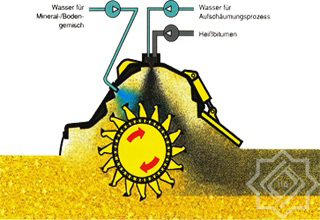

The potential of foamed bitumen for use as a soil binder was first realized in 1956. Since then, foamed bitumen technology has been used successfully in numerous countries with a corresponding evolution of the original bitumen foaming process as experience was gained in its use, the original process consisted of injecting steam into hot bitumen. The steam foaming system was very convenient for asphalt plants where steam was readily available, but it proved to be impractical for in-suit foaming

Operations because of the need for special equipment such as steam boilers.

Although the process of foamed bitumen (or bitumen emulsion) stabilization was developed more than forty years ago, the last decade has seen the technique flourish with further research being carried by organizations including Mobil and South Africa. Subsequently, many road authorities worldwide have carried out successful trials using foamed bitumen (or bitumen emulsion) stabilization technology.

The use of cement and foamed bitumen (or bitumen emulsion) as a rehabilitation options for averments is increasing internationally. Such methods are used recently in different countries such as, European, African and United States of America. The process has significant advantages in terms of i) lower quality aggregates can often be successfully used, ii) traffic disruption and time delays are limited by using an in-place milling, stabilization, mixing and placement operation, iii) foamed bitumen (or bitumen emulsion) and cement treated mixes have sufficient strength to be trafficked immediately without detrimental effects, iv) significant cost and time savings can be achieved and v) the method eliminates much of the heavy construction traffic that damages new construction and adjacent access and service roads.

Most stabilization of road materials carried out by 115 Construction Company has involved the use of bitumen emulsions, Portland cement and lime. The reasons for this are

- The stabilization agents are available.

- Equipment to incorporate the agents is available and proven in our Company.

- The performance of these agents is well documented

- Their use is considered cost effective.